Container Space Optimization

The goal of this project is to develop a solution for efficiently loading pallets of various sizes into a container, ensuring optimal space usage and structural stability while minimizing the risk of damage during transit. The solution will involve algorithms that:

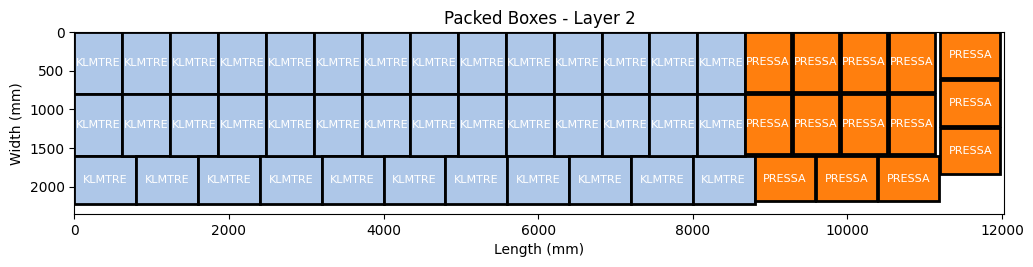

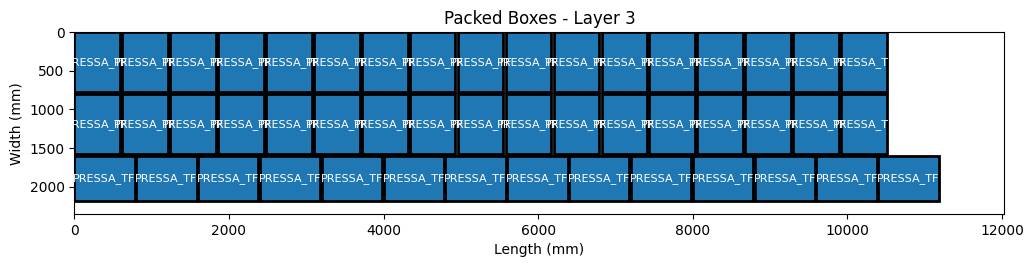

- Follow First-In-Last-Out (FILO) Loading: Pallets are loaded in the sequence they’ll be unloaded based on their destination, with priority on item unloaded last placed in first.

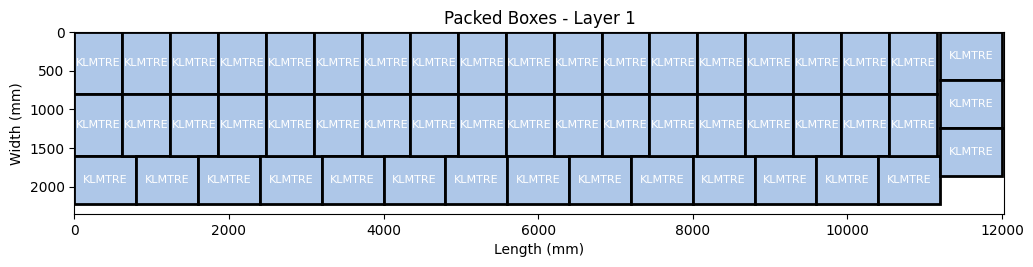

- Prioritize Large Pallets First: Pallets with the largest dimensions will be loaded first, with similarly sized pallets placed nearby to maximize space efficiency.

- Determine Optimal Orientation: Each pallet's orientation (horizontal or vertical) will be optimized based on available space before placement.

- Ensure Stability and Safety:

- Non-Overlapping Stacks: Top pallets must fit within the base pallet’s dimensions to avoid overhang.

- Weight Distribution: Stacked pallets must not exceed the load-bearing capacity of base pallets.

- Stacking Restrictions: Only two smaller units per pallet stack, no common base for top pallets, and full pallets cannot be placed atop top fillers.

- Controlled Rotation and Positioning: Pallets can be rotated for fit but cannot be tilted.

- Loading Layout: Loading starts from the driver’s side, organized in a 3-2-1 stacking configuration, without gaps, to further reduce damage risk.